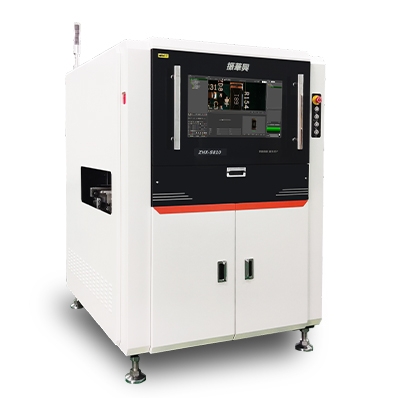

S820

Based on the optical principle of common defects encountered in welding production testing equipment.

Standard/Large On-Line AOI

活/多用途的AOIFlexible/Multi-function AOI

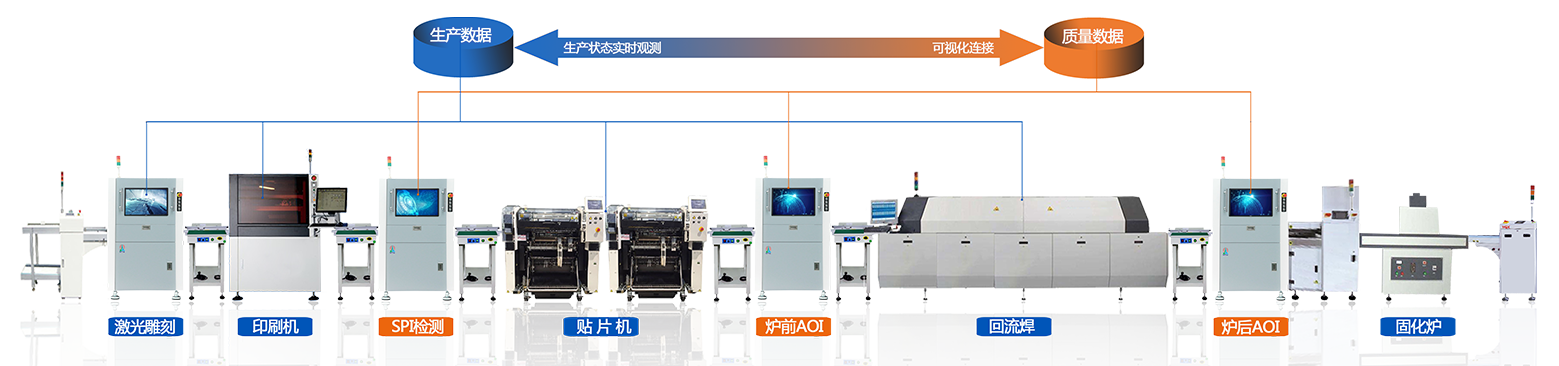

It can be placed at several quality controlling points in SMT Line to check 2D paste printing quality, inspect component defects before reflow soldering, inspect PCBA quality after reflip soldering and DIP wave soldering.

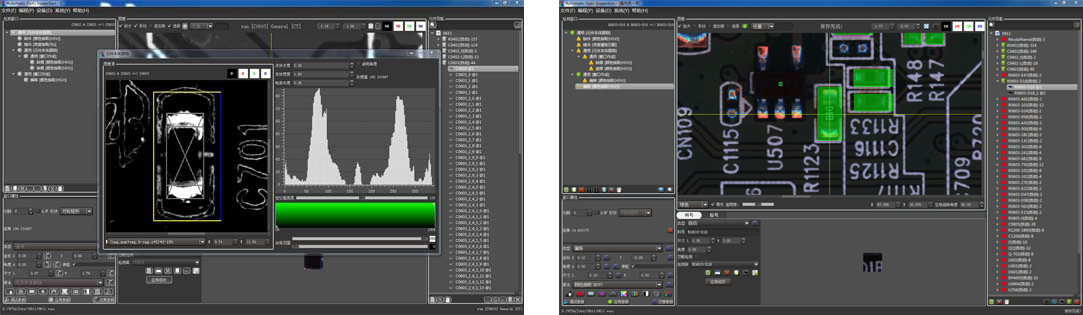

Various vector image algorithms to get the best inspection capability

The vector image algorithms include logic operation, distance of luminance boundary, chip tracing, OCR/OCV, luminance/color template matching, color distance, color extraction (RGB & HSV), value-range of luminance, offset of luminance, the minimum variation span of luminance, etc... More than 30 kinds of the most advanced algorithms.

Germany imported 5.0 Mp industry camera

With a high color reproduction, collocation a high-resolution telecentric Lens, high NG identification, provide high-definition image output for the AOI.

Import Control System

All major components are used internationally renowned brands. In the premise of ensuring the stability and accuracy of the movement equipment, with high service life and low failure rate.

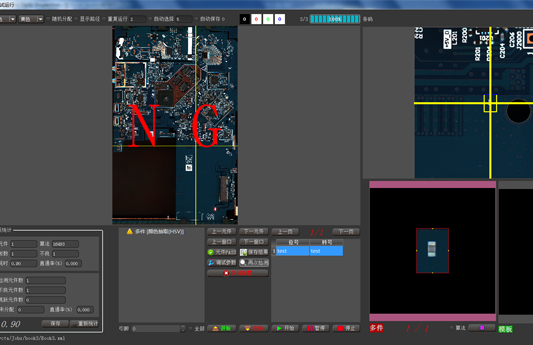

The entire PCB match capability can detect extra parts at any location.

The entire PCB match function High frame rate industrial cameras with telecentric lens, high-speed dynamic image acquisition can acquire hundreds of images per second, combined with the software's entire board matching algorithm, can be used detect extra parts, foreign matter, scratches and other information on the PCB.

Multi machines one operator, intelligent communication

Central server mode that gathers information from all the test machines to facilitate the integrated management of production, multiple machines need only one operator.

Consumer protection service items usually include "free warranty maintenance",

"regular return visit", "on-site training", "24-hour appeal response" and other

categories. We provide customers with the best equipment and perfect fast

service guarantee with the most sincere attitude.

● The equipment shall be guaranteed free of charge for one year and maintained

for life from the date of acceptance. The operationcontrol software of the sold

equipment shall be upgraded free of charge for life to ensure the latest software

version and optimization of functions.

● Call back and visit customers irregularly, communicate with customers in time

and improve relevant problems.

● The Customer Service Department shall respond to customer demands within

24 hours and within 2 hours after receiving them.

Overseas customers can provide nearby technical services or provide remote

training and technical support according to actual needs.